Pemberton Mill Collapse: Remembering One of the Worst Industrial Accidents of the 1800s

By Karen Harris | November 4, 2022

By the mid-1800s, the textile industry was booming in the New England states. With a ready supply of cotton from the South and new advances in machinery, the textile industry was supporting the economy of the region and providing an important commodity and a major export. In the midst of this economic growth, there was also disaster. When one of the textile mills, the Pemberton Mill, collapsed, killing scores of workers, the tragic event became a call to action for workplace safety. Here’s what happened with the Pemberton Mill collapse in 1860.

Prelude to Disaster

Built in 1853 in Lawrence, Massachusetts, the Pemberton Mill was a five-story brick building reinforced with metal beams. The structure, which was 280-feet long and 84-feet wide, was designed by engineer Charles H. Bigelow. John A. Lowell and his brother-in-law, J. Pickering Putnam, invested $850,000 – a considerable sum of money in those days, equal to about $28,000,000 in today’s dollars – in the building project. In less than four years, Lowell and Putnam sold the mill at a loss of about $350,000. The new owners, George Howe and David Nevins, St, cut as many corners as possible and took several questionable steps in hopes of turning the mill into a profitable venture as quickly as possible.

Overloaded and Overpacked

One way that Howe and Nivens tried to increase profits was to ramp up production. The more product they could turn out, the more money they would make. They hired more and more workers, mostly young immigrant women who had come to the United States from Ireland, Scotland, and Germany, to pack into the mill.

Howe and Nevins also invested in more machinery to boost output at the mill. The machinery was added to every floor of the five-story mill and when there was concern voiced about the added weight, the owners had some steel plates welded to the beams and girders for extra support.

Rolling in the Profits

Howe and Nevins’ business decisions paid off. By the start of 1860, the Pemberton mill had 700 looms and 2,700 spindles in operation. Roughly 600 employees worked at the mill, which was seeing annual profits of about $1,500,000, or about $44,000,000 in today’s money. The mill’s owners were happy with the profits and things were going along smoothly. They saw no need to improve the working conditions or the building itself.

The Collapse

On Tuesday, January 10, 1860, workers were crowded into the Pemberton Mill, doing their routine work. Just before 5 p.m. that afternoon, however, the workers heard an enormous snap. The walls and floors of the building buckled and suddenly collapsed on top of itself. Employees at a nearby mill watched the scene unfold before them. They later reported that the building collapse happened so quickly that very few people had a chance to escape before the walls crashed down on them. Interestingly, one of the few people who was able to escape as the mill was collapsing was its owner, George Howe.

Since every floor of the mill was laden with heavy machinery, hundreds of people were trapped in a tangled mass of wooden beams, bricks, and machinery. Dozens of people were killed instantly – rescue workers recounted stories of finding victims who were so mangled about the head and face that they were unrecognizable. Rescue efforts started immediately.

The Rescue

People of Lawrence, Massachusetts, flocked to the scene of the disaster. A quickly organized rescue effort was launched. As the sun set, several hundred people were pulled from the rubble, injured and bloodied, but still alive.

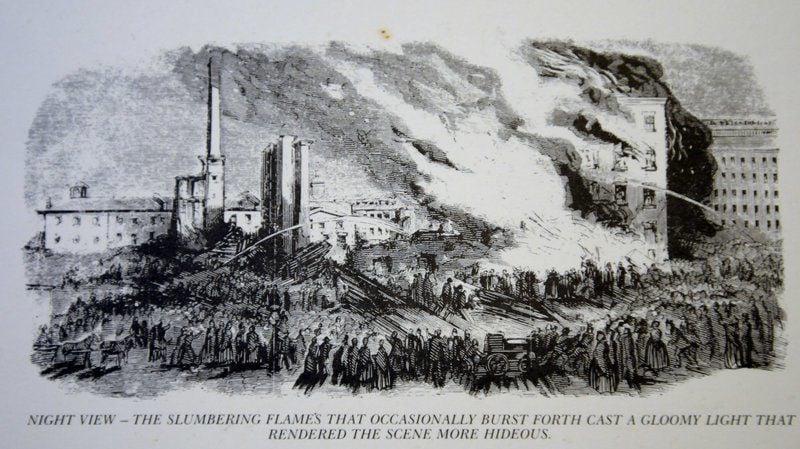

It is quite cold in January in New England. The rescue workers built several large bonfires to help warm them and the victims they were finding. The light from the fires also helped them to see into the debris.

Compounding the Tragedy

By 9:30 that night, there were sill hundreds of people still trapped in the collapsed mill. That is about the time that someone accidently knocked over an oil lantern. The flames quickly spread through the debris, fueled by raw cotton, textiles, wooden beams, and oil leaking from the machinery.

Rescue workers and family members watched and listened helplessly to the screaming of the trapped victims. Attempts to pull people from the debris were stymied as the fire gained strength, forcing rescuers back. It was a horrific scene. The local newspaper later reported that one man who was pinned under the wreckage tried to slit his own throat as the flames approached him. At the last minute, he was rescued from the debris only to succumb to his throat injury the next day.

In addition, there were reports of a dozen victims who could be seen by their families and were awaiting rescue who were burned alive in full view of their loved ones.

Eventually, the screaming stopped. When the smoldering pile of ash cooled and workers sifted through the debris, all that remained were charred bones of the remaining victims. More than 115 people died in the disaster and hundreds of others were injured.

What Caused the Collapse?

It was determined that the Pemberton Mill was not built to accommodate the extra weight of the additional textile machinery that Howe and Nivens had brought it. Since many of the machines were on the top two floors of the mill, it caused strain on the walls and beams. Further investigation determined that the building was poorly constructed in the first place. The metal beams were made of a lower-quality steel that was brittle, especially in cold temperatures. The bricks had not been properly mortars. Even the steel plates that Howe and Nivens added to reinforce the mill were not installed in the right places and were not strong enough to make up for the building’s initial shortcomings.

Learning from the Pemberton Mill Collapse

The collapse of the Pemberton Mill was an eye-opener for many people in the textile industry. Many mill owners prioritized profits over safety. They cut corners to increase their profit margin. George Howe and David Nivens, Sr. did not face any legal ramifications from the deadly collapse. In fact, they rebuilt the mill and continued on. But the Pemberton Mill collapse was a rallying cry for advocates of safe working conditions. The tragedy was cited as an example of the need to make factory owners accountable for workplace accidents, particularly preventable ones in which the owners were negligent.